Online Fabric Defect Control Systems

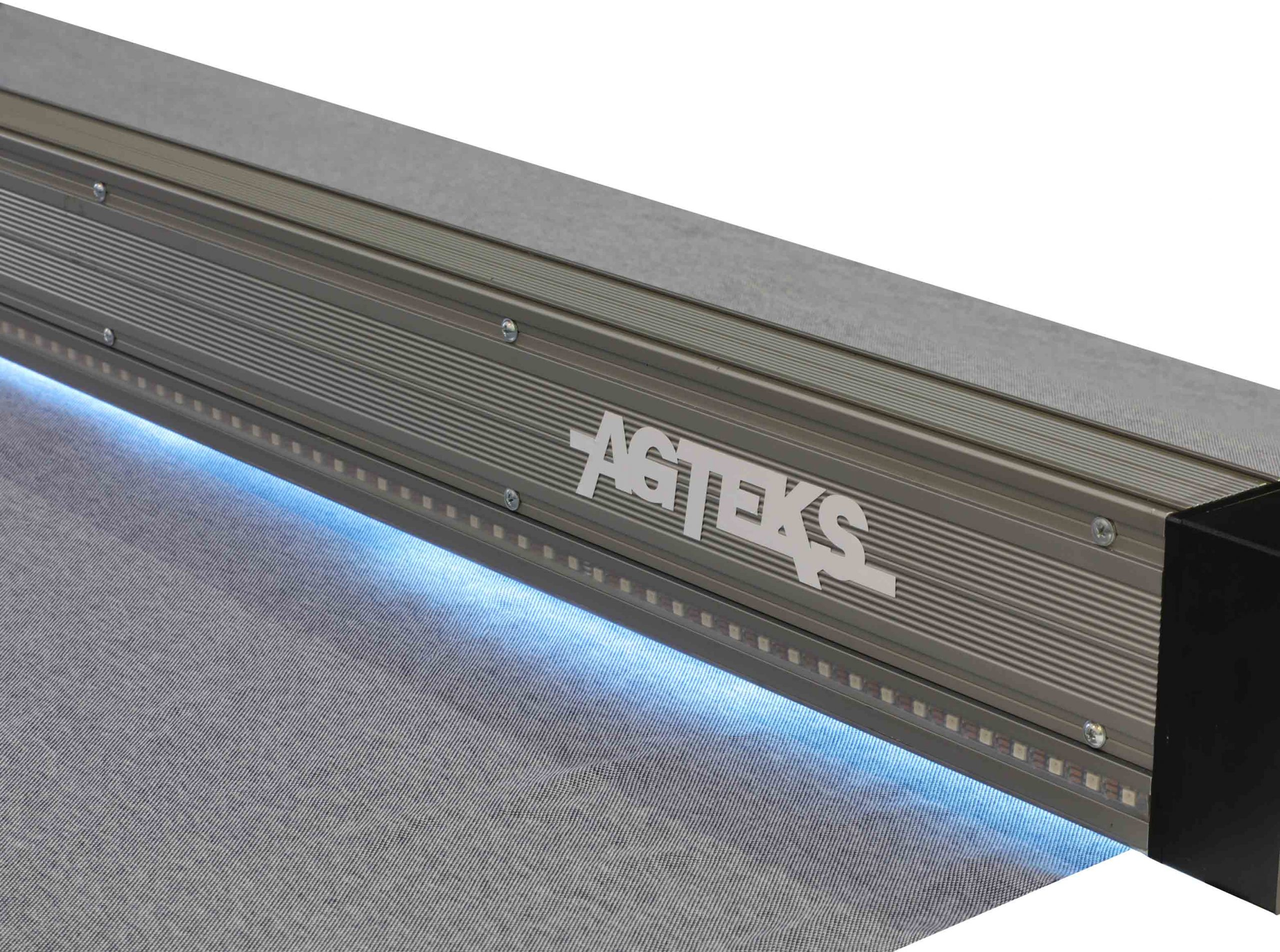

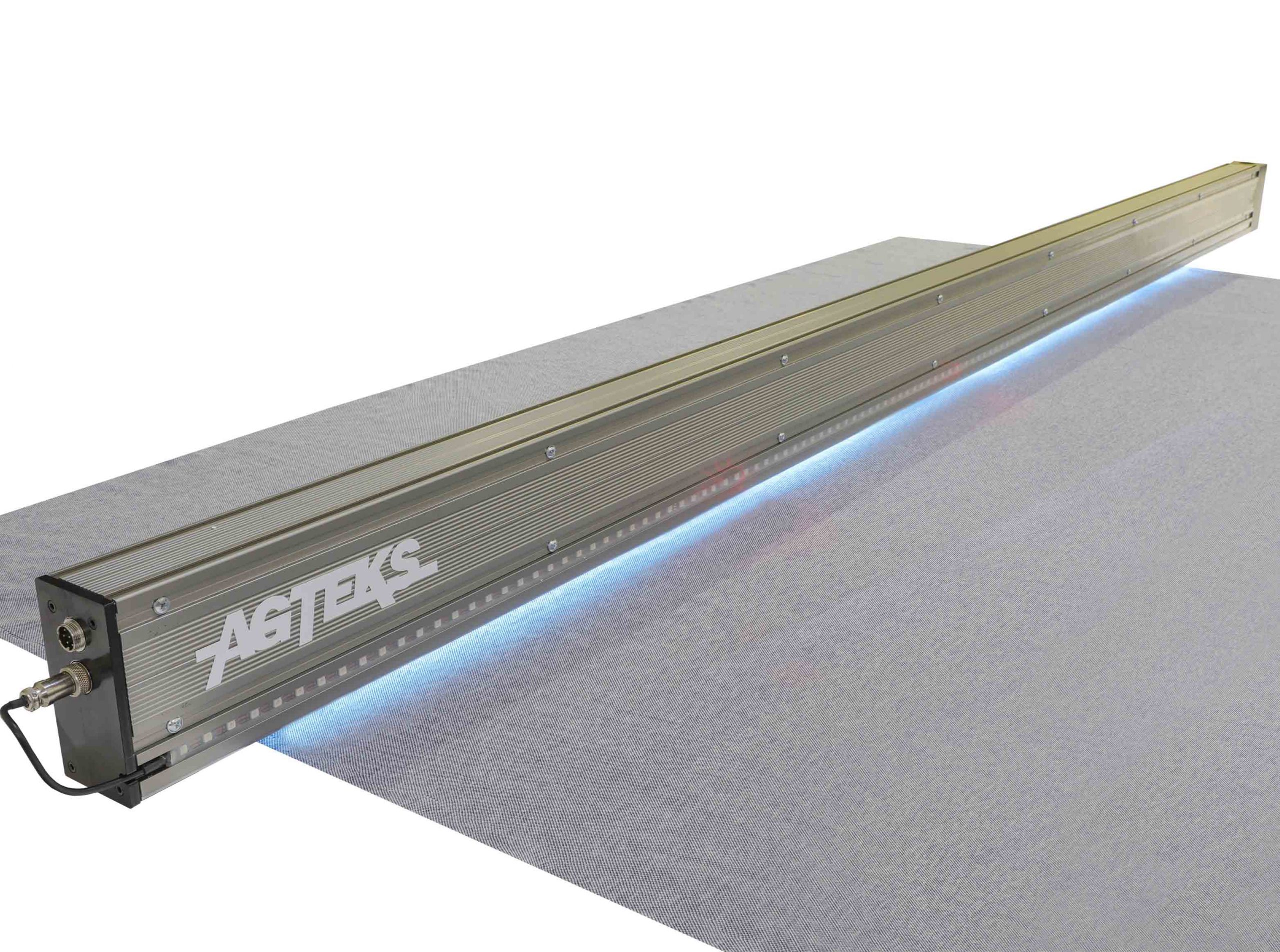

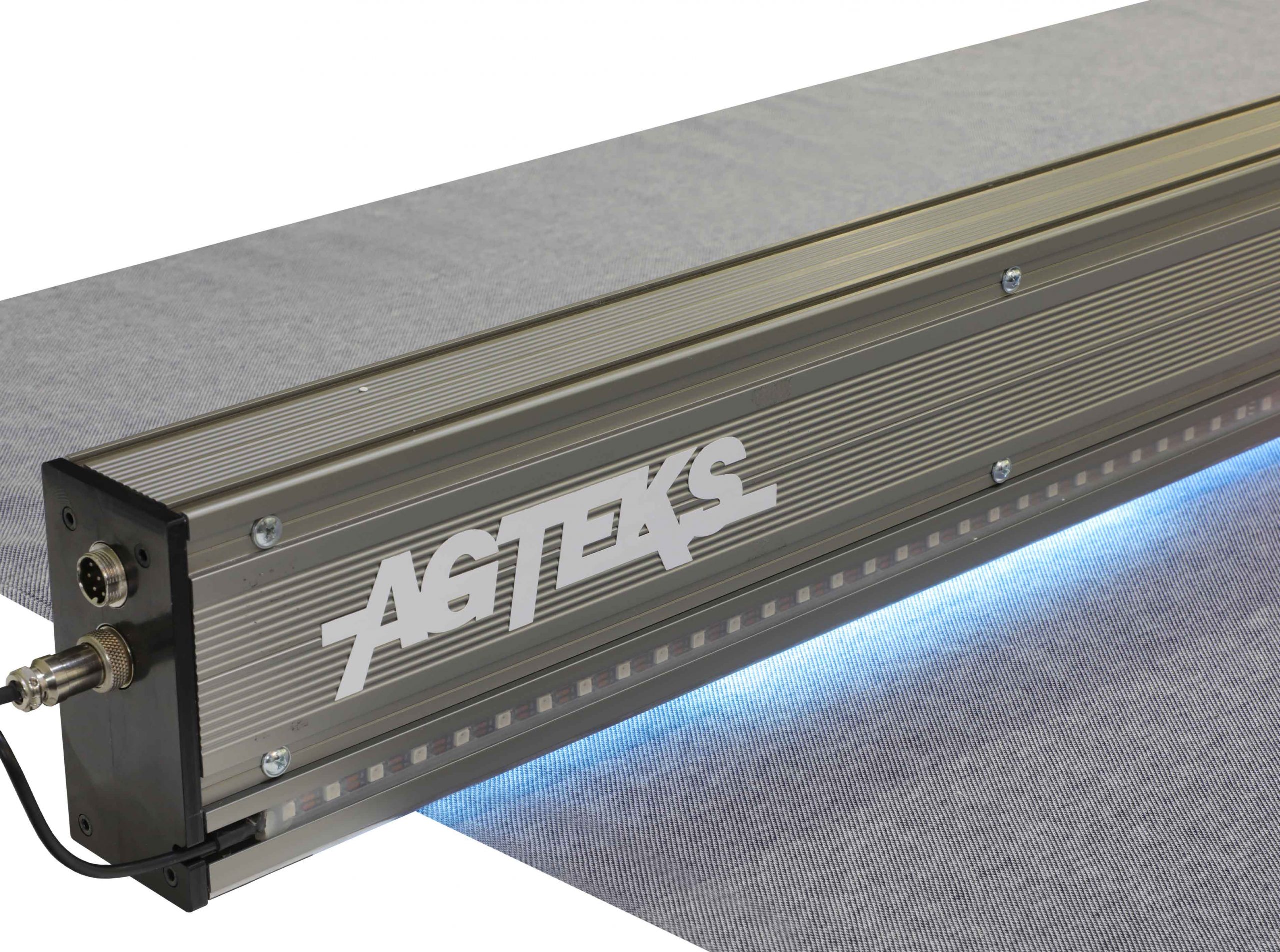

Quality Bar

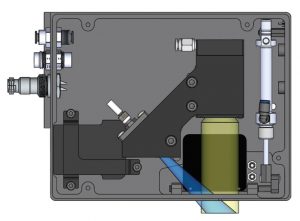

Quality Bar simultaneously detects, names and reports visual defects on the fabric. Designed with artificial intelligence and deep learning algorithms, Quality Bar provides fabric quality control with a 95% accuracy rate by eliminating the human factor in a compact feature. Quality Bar, one of the pioneers of Industry 4.0 breakthrough in the textile sector, is an “intelligent” quality control system.

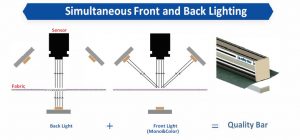

Quality Bar provides quality control with its multi-mode scanning system and light sources reflected on the fabric. It is a real high-resolution online fabric quality control system with simultaneous front and back lighting.

Quality Bar detects point, horizontal and vertical defects on the fabric. Classifies and reports with a user-friendly interface.

| Technology | High-speed scanning sensor |

| Sensor Resolution | Up to 600 dpi |

| Scanning Width | Up to 6 meters |

| Scanning Speed | Up to 50 meters/minute |

| Detection Speed | 6.000 lps |

| Defect Detection | fabric defect, weft defect, warp defect |

| Fabric Type | Woven, nonwoven or knitted fabric |

| Program Control | Multi-core embedded computer control |

| Recording | Defect time, defect location (x,y) on the fabric, machine number, defect size, defect picture, defect name and so on |

The Quality Bar has high precision and especially designed to achieve high-speed online fabric inspection processes. Equipped with high-resolution algorithms, Quality Bar can reach a working speed up to 50 m/min. Quality Bar can work with 20K or 40K resolution with a working width of 2 meters.

• Scan resolutions can be selected as 300 or 600 dpi.

• Fabric speed is dependent on resolution characteristics.

Online Fabric Defect Control Systems

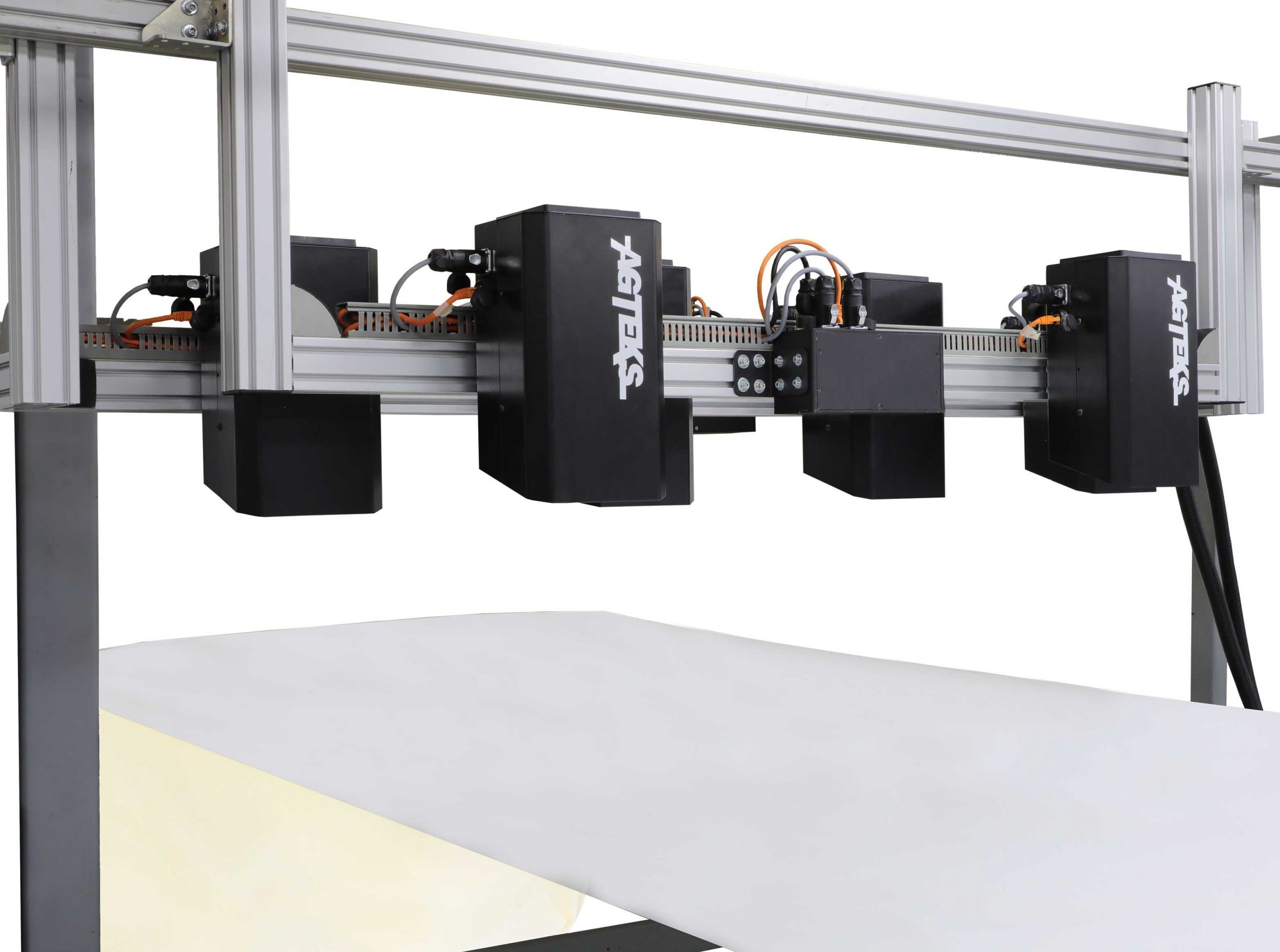

Finishing Bar

Finishing Bar is the system that detects online the defects on the fabric and determines their locations and type with cameras. The cameras make the detection process with the help of light sent from stable light sources.

| Technology | High-speed scanning sensor |

| Camera Resolution | Up to 8K |

| Scanning Width | Up to 6 meters |

| Scanning Speed | Up to 450 meters/minute |

| Detection Speed | 26.000 lps |

| Defect Detection | Fabric defect, weft defect, warp defect |

| Fabric Type | Woven, nonwoven or knitted fabric |

| Program Control | Graphic display on PC |

| Recording | Defect time, defect location (x,y) on the fabric, machine number, defect size, defect picture, defect name and so on |

İçerik Gelecek…

Online Fabric Color Variation Control Systems

Shade Bar

Shade Bar is an online quality control system that detects edge differences, color filtering and lot differences that may occur in the production of dyed fabrics with a spectrophotometer.

Shade Bar calculates Delta E differences by measuring L, a, b values on the flowing fabric instantly. It provides benefits in terms of quality and time in subsequent production processes.

The Shade Bar provides continuous color controls by measuring the optical reflectance values of the fabric. If necessary, it can also send a “stop” command to the machine during detection. ShadeBar, another pioneer of Industry 4.0 breakthrough in the textile industry, can send the calculated data to computer memory, cloud environment or web provider.

ShadeBar makes color measurements in accordance with the recommendations and decisions of the International Commission on Lighting (CIE-Commission Internationale de l’Eclairagel).

| Technology | High precision spectrometer |

| Spectral Sensitivity | =< 3 nm |

| Scanning Speed | 100 measurement/second |

| Measurement Spectrum Range | 380 – 780 nm |

| Defect Detection | Wing differences, color filtering |

| Communication | Ethernet or Wi-Fi |

| Recording | Defect time, defect location (x,y) on the fabric, machine number, defect size, defect picture, defect name and so on |

The Shade Bar is equipped with high sensitivity spectrophotometers and long-life LED lighting beams with high CRl. The Shade Bar automatically calibrates with a pair of “dark and light” colored plates held under positive pressure.

With the help of 3 spectrophotometers inside the Shade Bar, it makes continuous measurements on the left, middle and right sides of the fabric and detects the wing differences that will occur. It also gives the difference in color percolation that occurs along with the flowing fabric. Calculates Delta-E differences according to CIE2000, CMC2:1, CMC1 :1 standards.

The fabric is illuminated by a beam of light under an incidence angle of 10°, the rays reflected from the fabric surface at a reflectance angle of 45° ± 5° are collected and measured.

Online Fabric Color Variation Control Systems

Shade Lab

Shade Lab is a desktop spectrophotometer that measures the color values of textile materials.

Shade Lab, Unlike conventional spectrophotometers, makes the most accurate measurements on pile surfaces and in-grained structures.

Shade Lab, makes color measurements based on the recommendations and standards of the International Commission on Illumination [CIE-Commission Internationale del’Eclairage] by means of a spectrophotometer.

| Technology | Monolithic structured high precision micro spectrometer |

| Spectral Sensitivity | =< 3 nm |

| Measurement Accuracy (Delta E) | =<0,05 |

| Measurement Spectrum Range | 380 – 780 nm |

| Measurement Area | 15 mm diameter |

| Source of Light | Sunlike LED |

| Recording | Recording reference and Measurement values |

Shade Lab measures 360 degrees on the surface by means of its patented rotating platform. It reaches the clearest results with equal measurement times and exposure for each grade.

Shade Lab, is another helpful factor in minimizing light reflection and refraction at different angles with its special colored calibration plate designed for 3D textile products (woven knitted velvet, flock, chenille yarn & fabric).

Shade Lab, uses the Delta E 2000 measurement principle, which entered the literature in the early 2000s and is calculated with the minimum effect of the reflectance value, for 3-dimensional surfaces.