Online Yarn Quality Control Systems

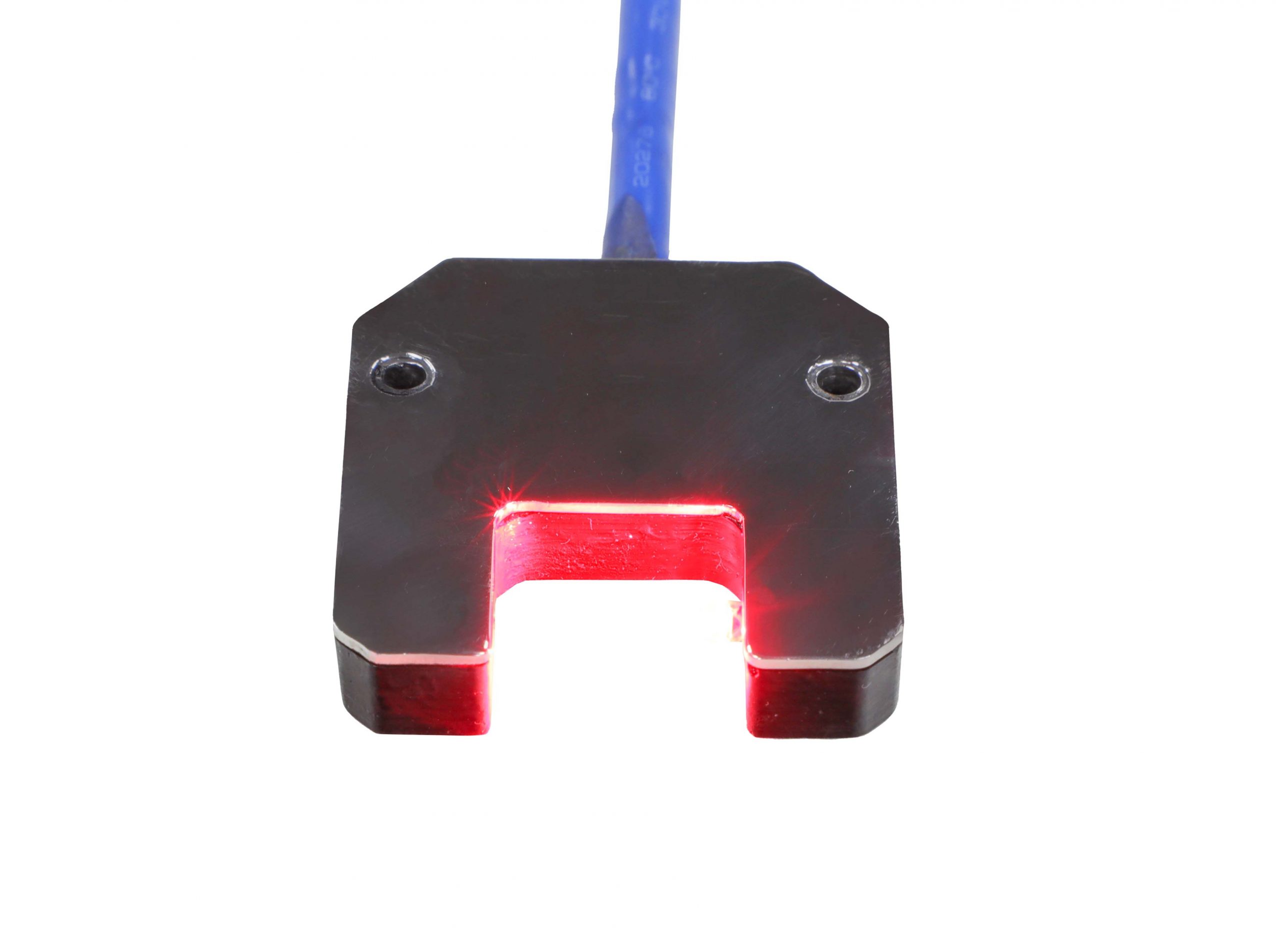

Quality Eye

Quality Eye is the quality control unit for detecting the structural defects of the yarn in twisting and winding machines. These sensors, which can measure up to 100 meters per minute, instantly measure and report the yarn quality.

Quality Eye detects and reports all quality issues such as yarn breakage, thickness variation**, slub, lump**, splice recognition. It can measure the length, thickness, hairiness and tension of the yarn. With its user-friendly operator panel, it can also send a “Stop” command to the machine when necessary.

| Sensor Type | Photo Diode |

| Pixel count | 1 |

| Renovation | None |

| Axis | No axis |

| Dtex value | Immeasurable |

| Sensor signal | Relative change |

| Pollution level | None |

| Yarn speed | Up to 2.500 meters/minute |

Quality Eye uses high-resolution scanning sensors and infrared lights specifically designed for yarns of all colors. With 600 dpi resolution and an 8 mm scanning area, the scanning speed can go up to 1.000 lines per second.

Quality Eye learns the yarn thickness in the first few seconds after starting the machine. Then, it starts measuring percentages of relative changes in thickness, hairiness and so on.

Online Yarn Quality Control Systems

High Speed Quality Eye-1D

HS-Quality Eye-1D is a one-dimensional yarn quality control sensor with optical scanning technology. Detects and reports online structural defects such as lumps, knots, and joints on winding and texturing machines. It can also send a “Stop” command to the machine when necessary.

| Sensor Type | Linear image array |

| Pixel count | 128 |

| Renovation | 400 dpi |

| Axis | 1-axis |

| Dtex value | Absolute value |

| Sensor signal | Absolute thickness |

| Pollution level | Yes |

| Yarn speed | Up to 6.000 meters/minute |

HS – Quality Eye uses high-resolution scanning sensors and backlights specially designed for yarns of any color. 400 dpi resolution, 8 mm scanning area with scanning speed per second. It can go up to 30.000 lines.

Online Yarn Quality Control Systems

High Speed Quality Eye-2D

HS – Quality Eye 2D is a two-dimensional yarn quality control sensor with optical scanning technology. It detects and reports the thickness variation online, as well as the structural defects of the yarn such as lumps, knots, joints in the winding and texturing machines in the yarn production lines.

| Sensor Type | Linear image array |

| Pixel count | 2 x 128 |

| Renovation | 2 x 400 dpi |

| Axis | 2-axis |

| Dtex value | High Accuracy absolute value |

| Sensor signal | Absolute thickness |

| Pollution level | Yes |

| Yarn speed | Up to 6.000 meters/minute |

HS – Quality Eye uses high-resolution scanning sensors and backlights specially designed for yarns of any color. 400 dpi resolution, 8 mm scanning area with scanning speed per second. It can go up to 30.000 lines.

Online Yarn Quality Control Systems

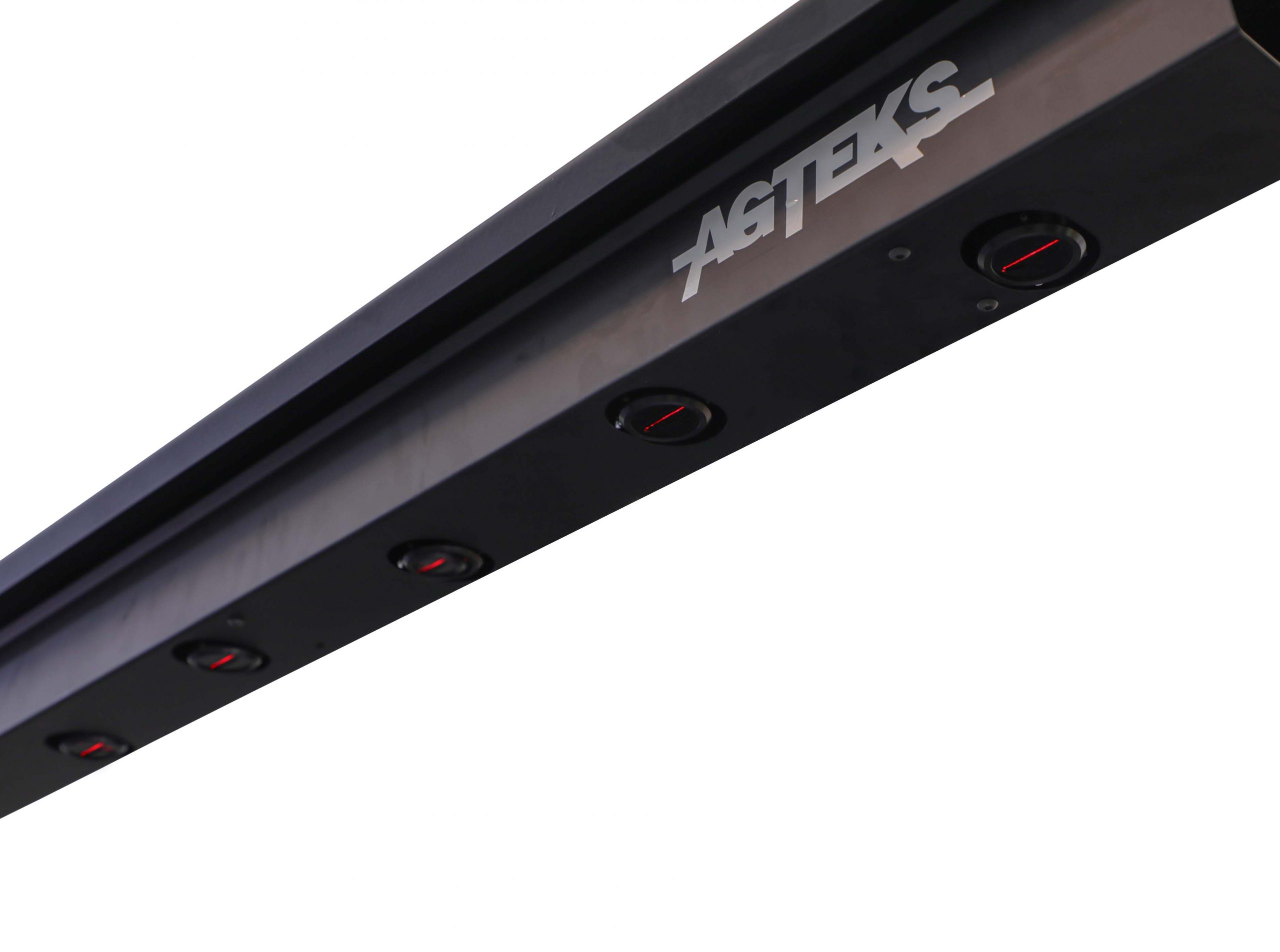

Digital Dropwire

Digital Dropwire is an intelligent digital lamella system developed instead of mechanical lamella system in warping and rope opening processes. It provides tracking of yarns online.

Digital Dropwire detects the number of yarns in the warping and automatically stops the system when the yarn breaks.

| Technology | High-speed scanning sensor |

| Sensor resolution | Up to 600 dpi |

| Scan length | Up to 600 cm |

| Detection speed | 6.000 lps |

| Defect detection | Yarn break, yarn defect |

| Contact | Ethernet or Wi-Fi |

| Output | 2 pcs NPN, open collector, max 50mA |

| Recording | Defect time, defect location, machine number, defect name |

Digital Dropwire is equipped with specially designed high-resolution scanning sensors.

Digital Dropwire can reach up to 600 meters per minute online with the support of artificial intelligence image processing algorithms.

With its backlight source technology, Digital Dropwire automatically learns the yarn count, regardless of color and thickness, and displays it on the screen. With its user-friendly touch screen, automatic stopping is provided in the desired quantities.

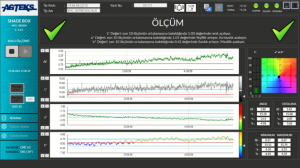

Online Yarn Color Variation Control Systems

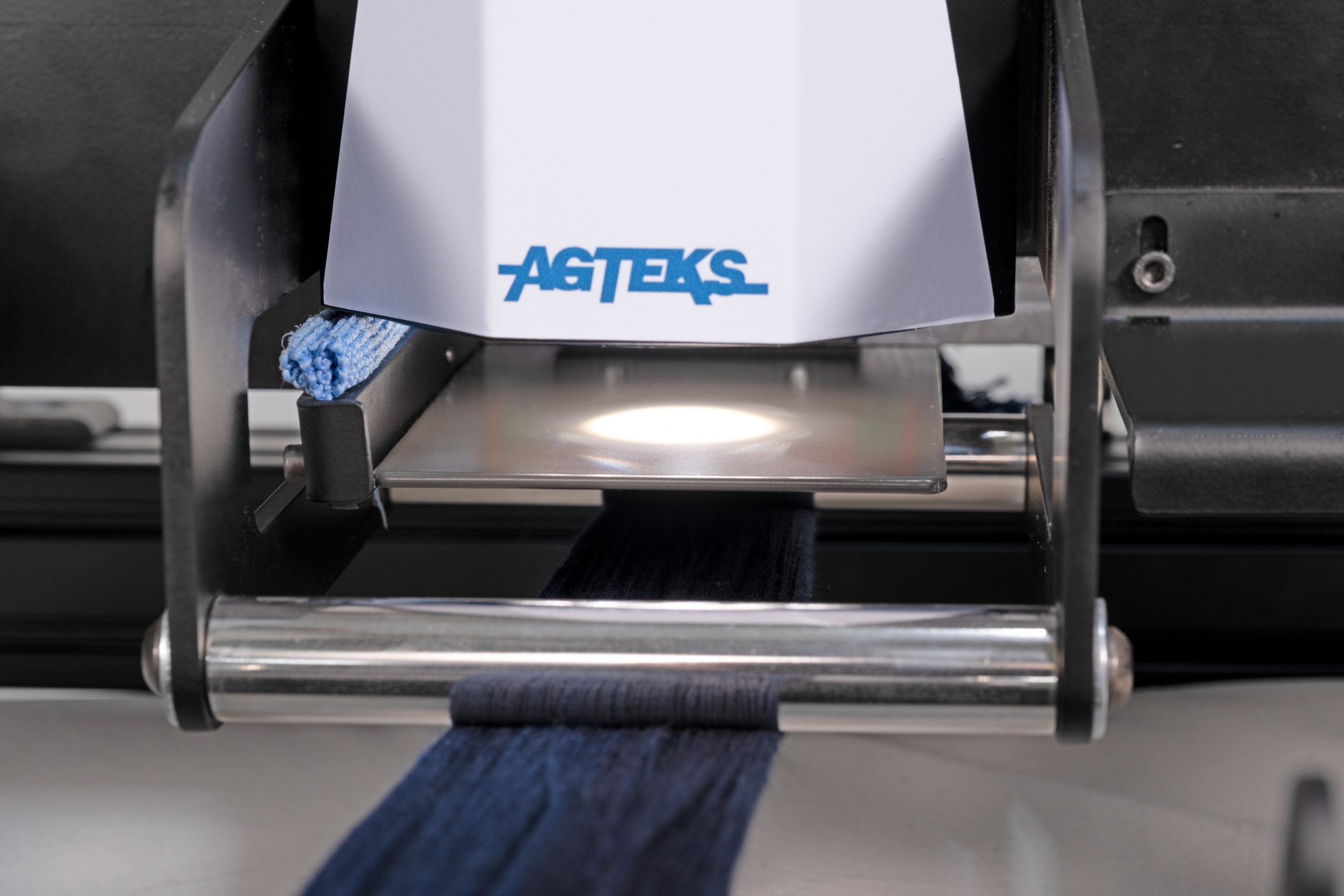

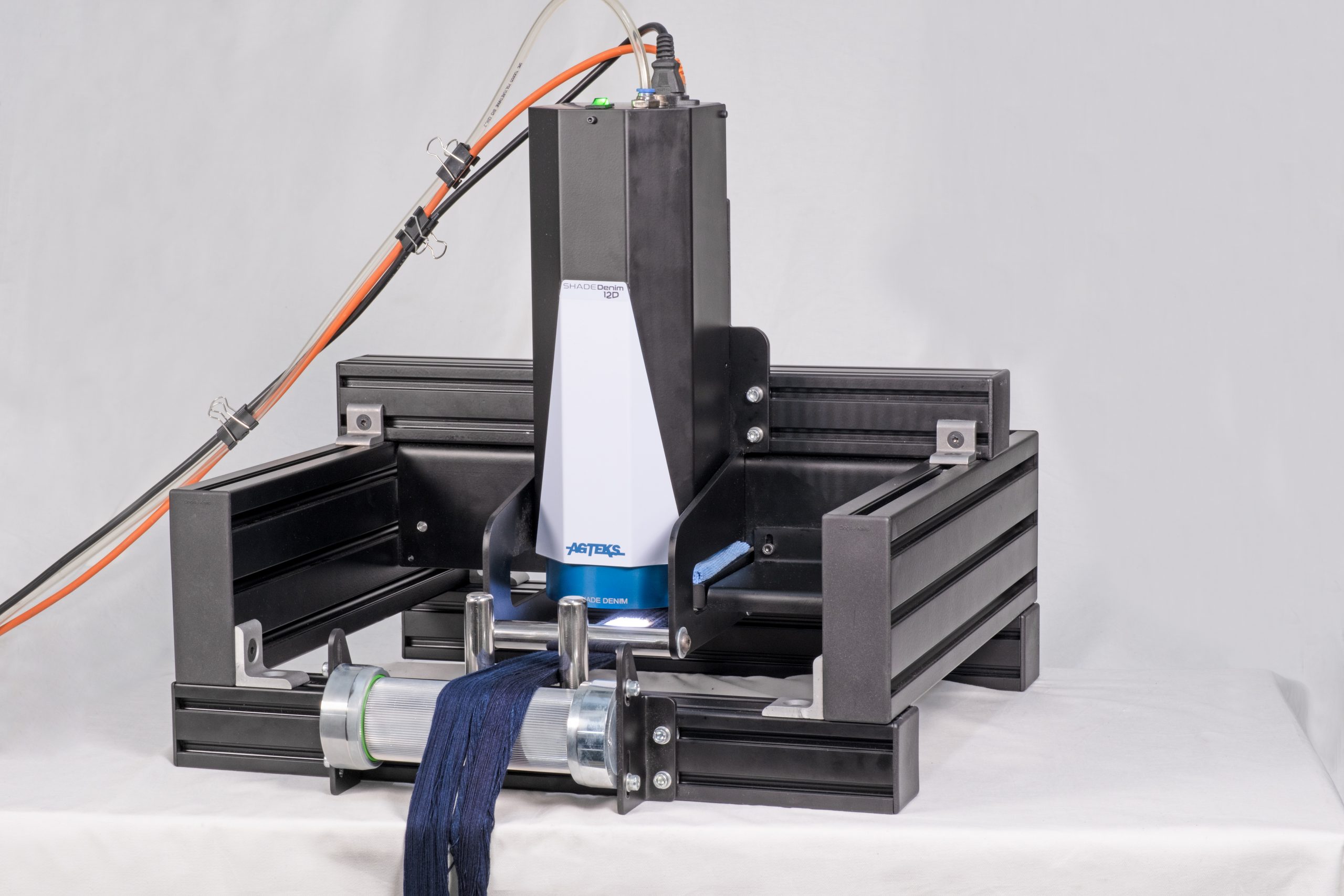

Shade Denim

Shade Denim is an online quality control system that detects the color variation that occurs during the production of dyed denim yarns with a spectrophotometer.

Shade Denim makes color measurements in accordance with the recommendations and decisions of the International Commission on Lighting [CIE-Commission Internationale de l’Eclairage].

| Technology | Monolithic structured high sensitivity microspectrometer |

| Sensor resolution | 1.024 dpi |

| Scanning speed | 100 measurement/second |

| Spectral Resolution | <= 3nm |

| Spectrum measurement range | 380 – 780 nm |

| Measurement area | Diameter 30-50 mm |

| Measurement accuracy | <= 0,05 |

| Source of light | LED |

| Defect detection | color differences, shade differences |

| Contact | Ethernet or Wi-Fi |

| Display | OLED |

| Output | NPN, open collector output, max 50mA |

| Parameter input | Touch screen |

| Program control | Multi-core computer control |

| Recording | Defect time, defect length (time based) machine number, defect code, meter |

Archive interface. All CIE L*a*b values and color difference (ΔE) values can be checked at any time with the historical measurement archive.

Archive interface. All CIE L*a*b values and color difference (ΔE) values can be checked at any time with the historical measurement archive.

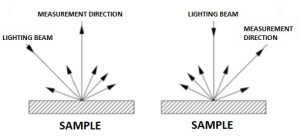

45/0 and 0/45 standard monitoring and lighting geometries

1.3.1.1: 45° – 0° Geometry

In this geometry, the sample is illuminated by a light beam at an incident angle of 45° ± 5°. The light beams reflected from the sample surface under a reflection angle of at most 10° are collected and measured. This geometrical condition is briefly denoted as 45/0.

1.3.1.2: 0° – 45° Geometry

In this geometry, the sample is illuminated by a beam of light under an incident angle of 10°. The rays reflected from the sample surface at a reflection angle of 45° ± 5° are collected and measured. The dispersion of the reflected (observed) light beam should not be more than 5° relative to its axis. This geometrical condition is briefly denoted as 0/45.

Online Yarn Tension Measuring Systems

Smart Guide

Smart Guide is a system that measures 360-degree tension of yarns with smart bead technology. It allows the use of creel exits or in all passageways of the yarn. It can also send a “Stop” command to the machine when necessary.

There are 3 different models in Smart Guide;

Model A: 0-300 cN, precision ± 5 cN

Model B: 0-500 cN, precision ± 5 cN

Model C: 0-1000 cN, precision ± 5 cN

Online Yarn Tension Measuring Systems

TensionBar

TensionBar is a system that can measure and report the tension of each yarn in multiple yarn working areas. If necessary, it can also send a warning and “Stop” command to the machine.

Tension Bar has 3 different models;

Model A: 0-300 cN, precision ± 5 cN

Model B: 0-500 cN, precision ± 5 cN

Model C: 0-1000 cN, precision ± 5 cN