for Stable Yarn

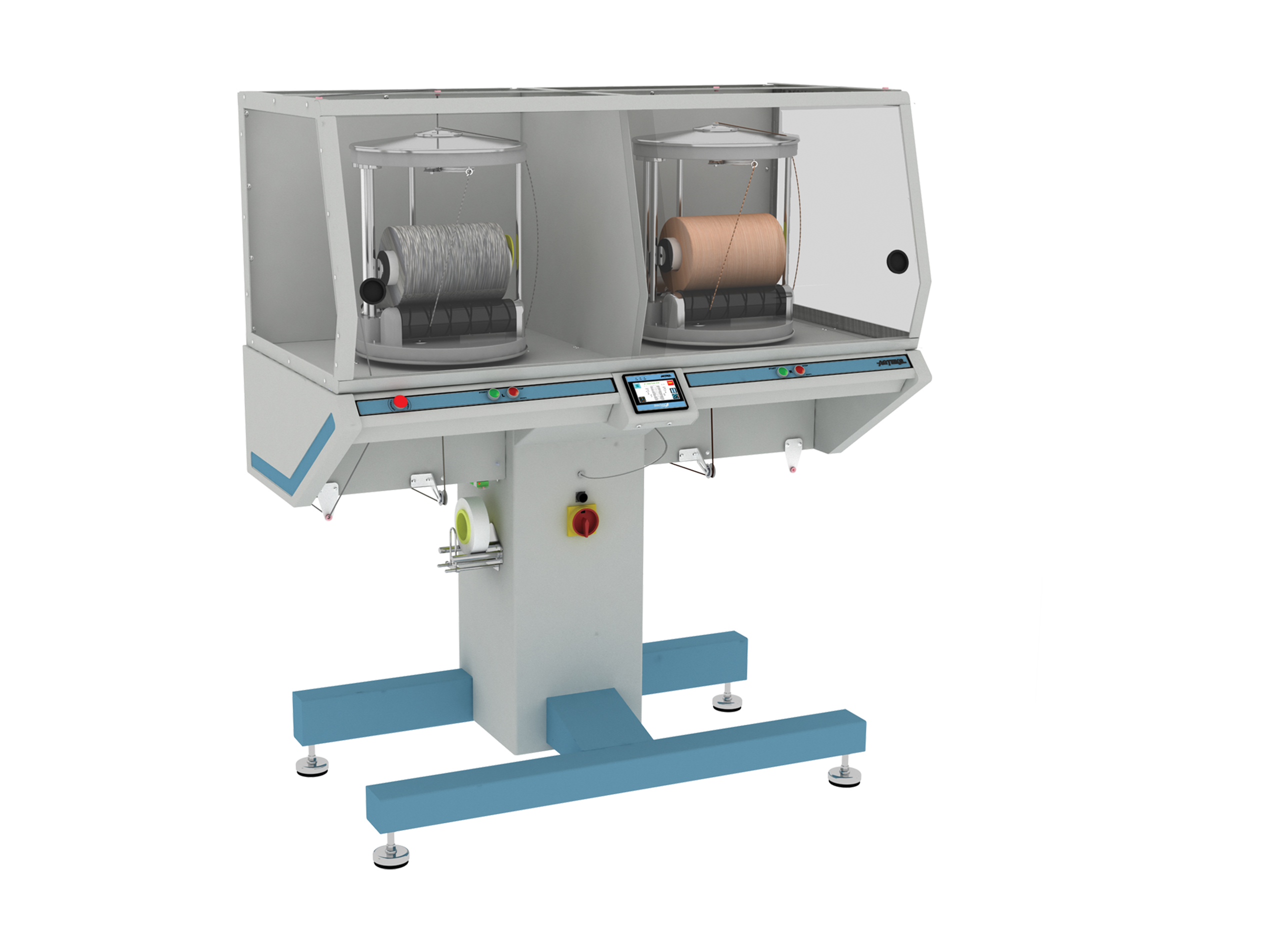

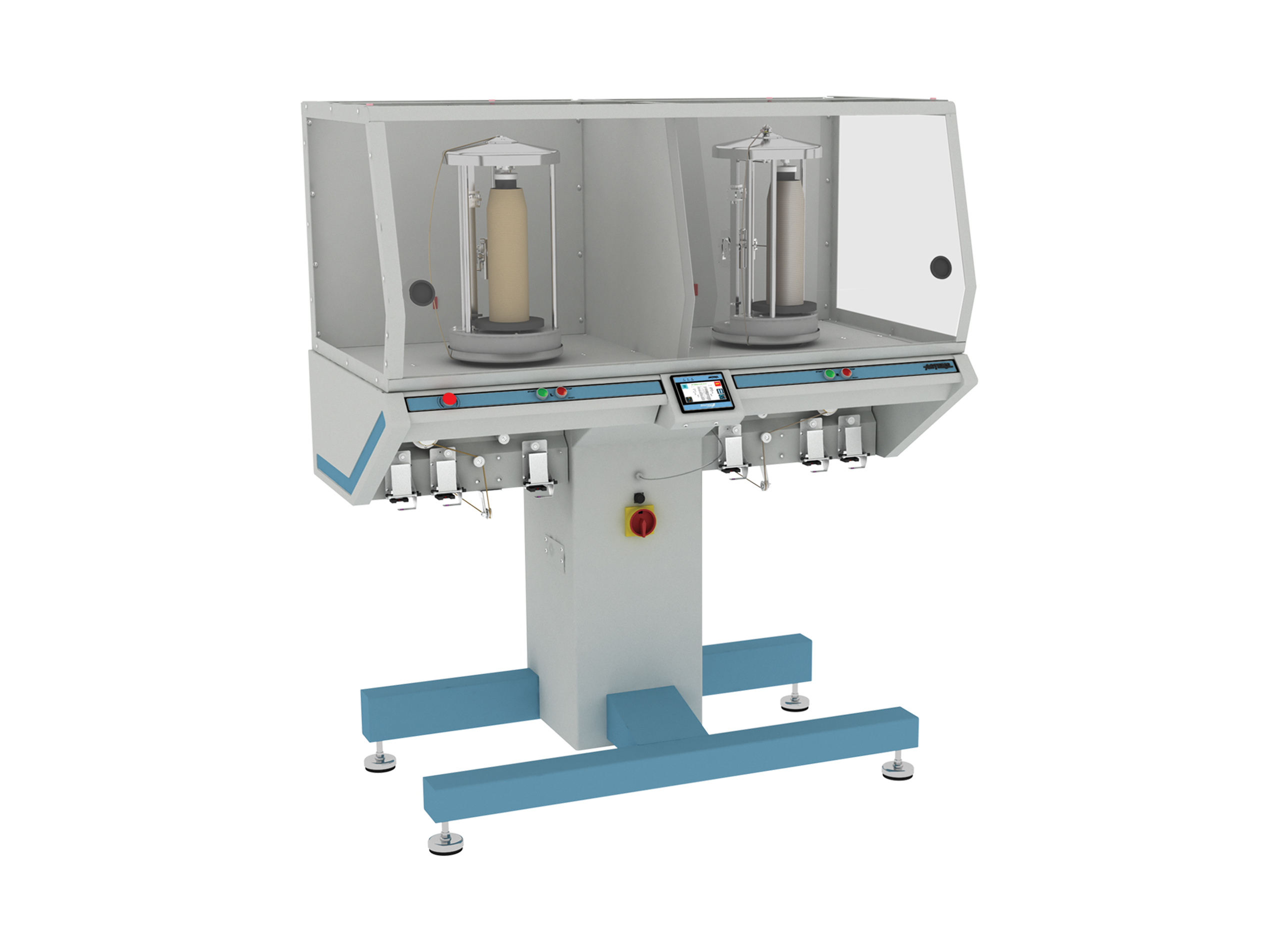

DirecTwist ® 2B6”

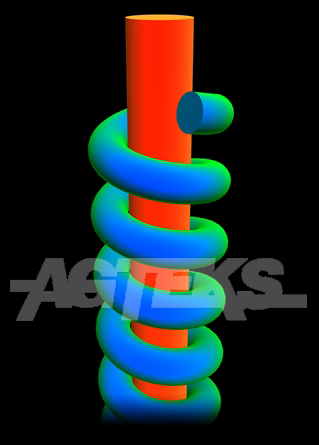

You can perform your twisting and covering processes in the fastest way with your staple fiber yarns and, you can express your creativity at the same time.

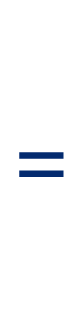

Thanks to its touch screen, it is possible to set the parameters you would like to run. You can produce the combinations you dream of with the highest level of precision in this machine equipped with the highest technologies.

You can quickly get your final yarns by placing your bobbins bottom of the machine. DirectTwist-2B6” is very suitable for use in factories, research laboratories and showrooms thanks to its compact design.

| Maximum twisting speed | Up to 18.000 twist/minute |

| Maximum twist value | Up to 2.000 twist/meters |

| Maximum production speed | Up to 200 meters/minute |

| Total twisted yarn thickness | 100 Nm to 1.8 Nm (~90 Denier to ~5.000 Denier) |

| Take-up cone size | 170 mm length conical cone |

| Max. take-up cone diameter | 220 mm |

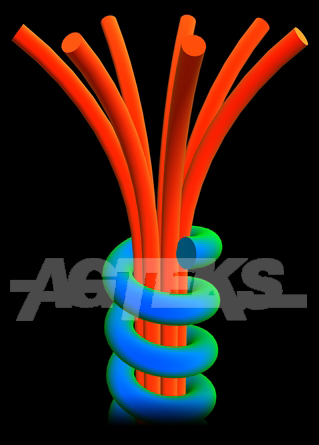

| Max. yarn plies to be twisted | Unlimited |

| Yarn break sensors | 8 sets optical sensors and the optional capacitive sensor for elastane |

Optional Programmable Elastane Feeder

It feeds your Lycra/Elastane yarns at a rate of 10%-90% and allows them to be twisted together with any type of yarn.

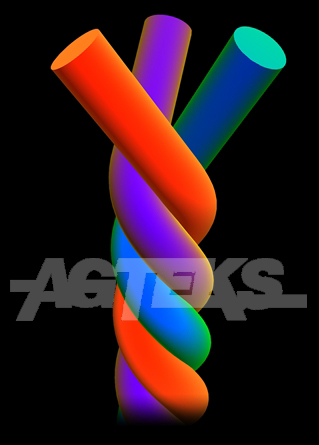

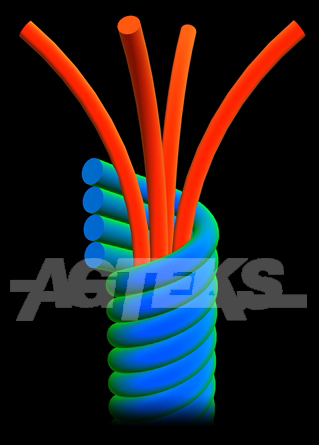

PreTwist-C

It allows the S and Z twisting of your yarns to be done in a single operation. PreTwist-C can be produced up to 7 heads. It helps you to perform the S+Z operation you request as quickly as possible.

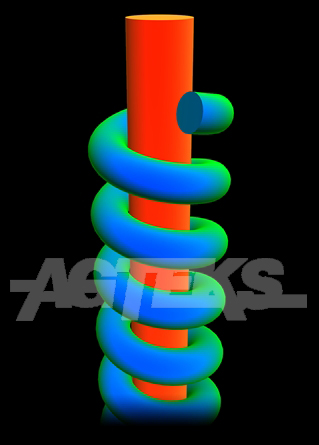

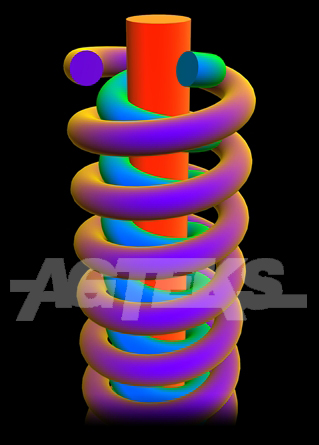

Twisting and Covering is easier than ever!

You can realize combinations of your dreams with different twisting and covering methods on the same machine.

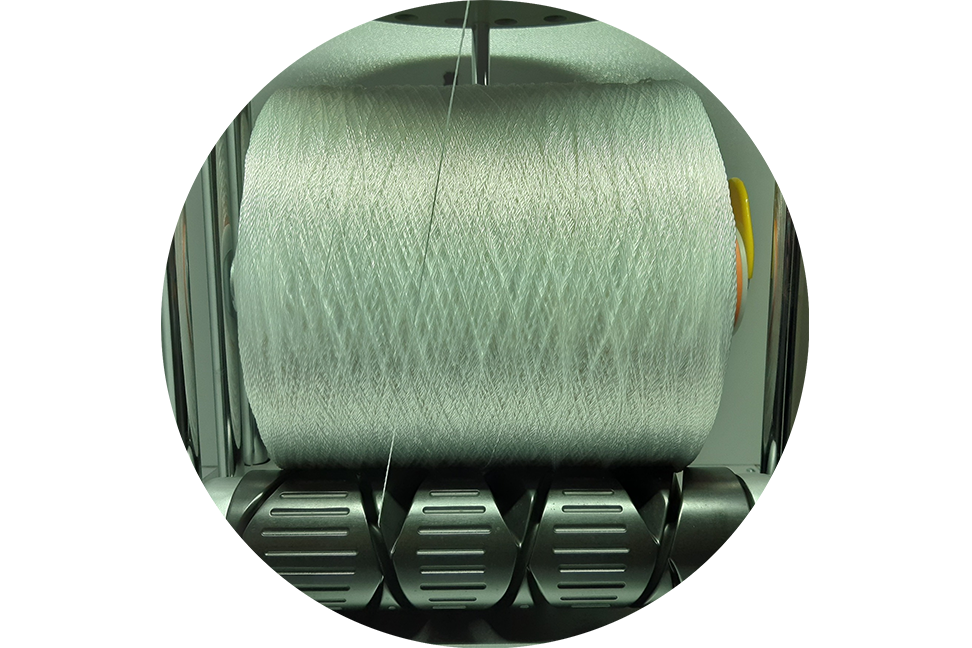

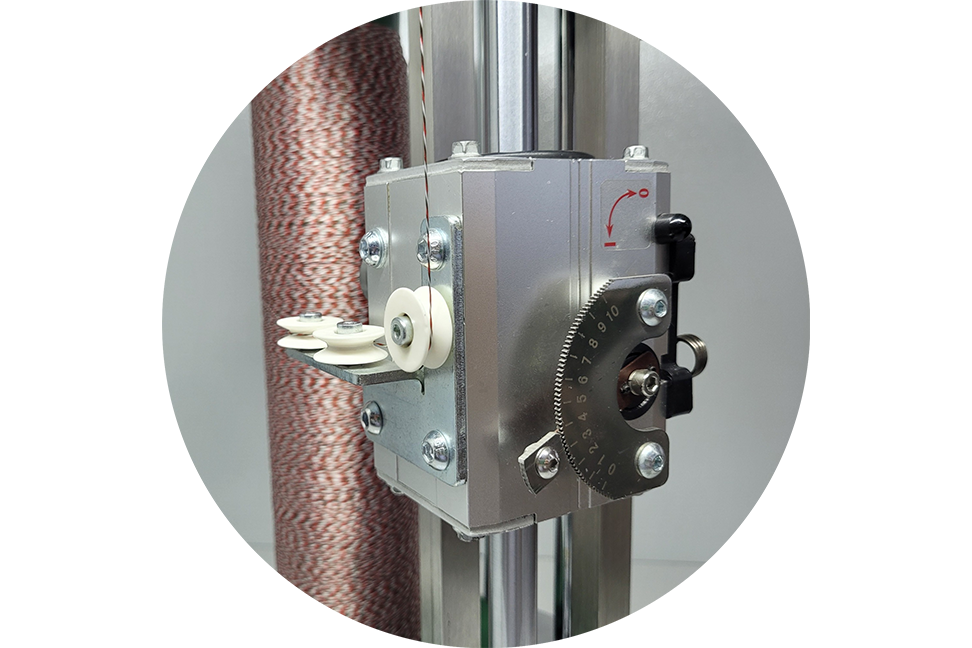

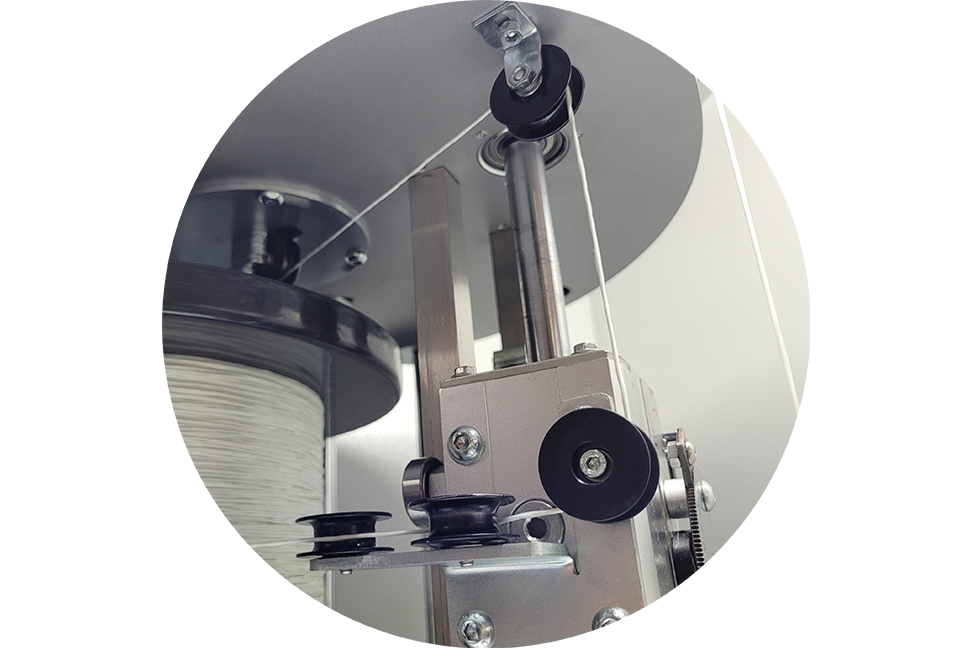

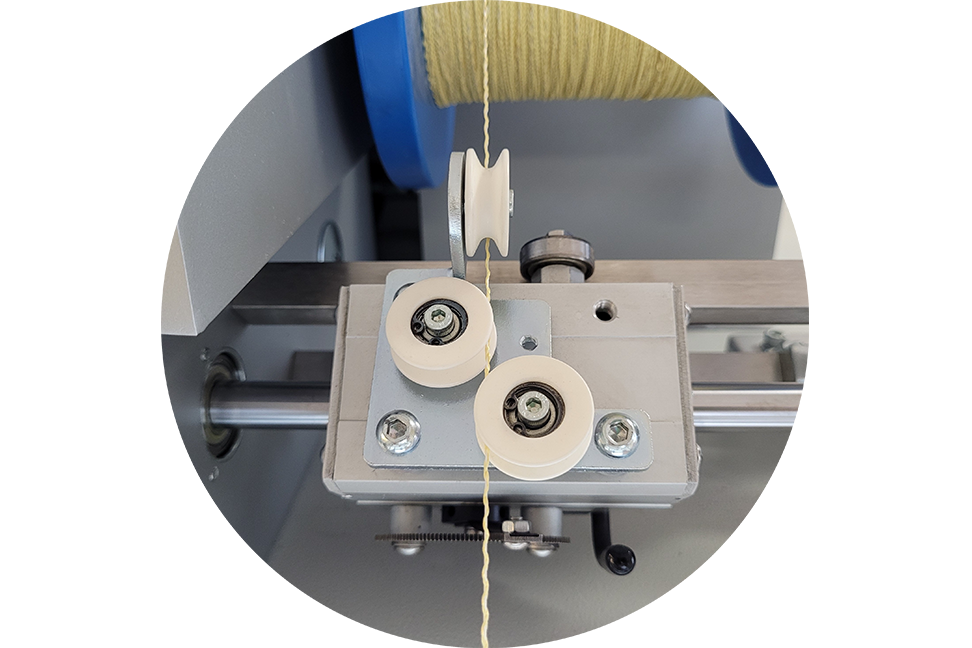

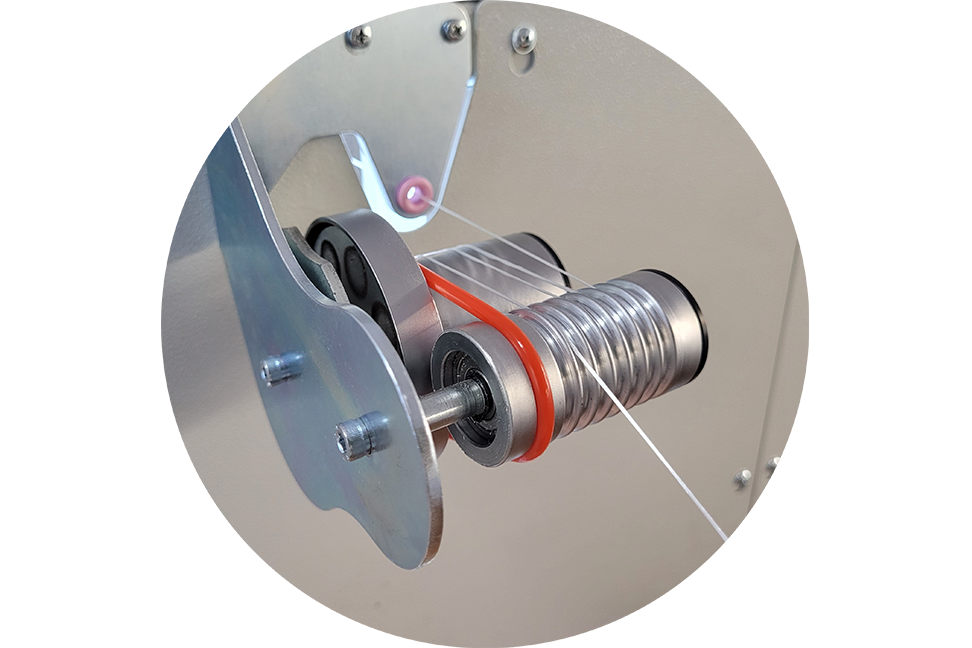

Precise yarn feeding systems

You can maximize the efficiency of the winding and twisting process with the yarn feeding system.

Optional Programmable Elastane Feeder

It feeds your Lycra/Elastane yarns at a rate of 10%-90% and allows them to be twisted together with any type of yarn

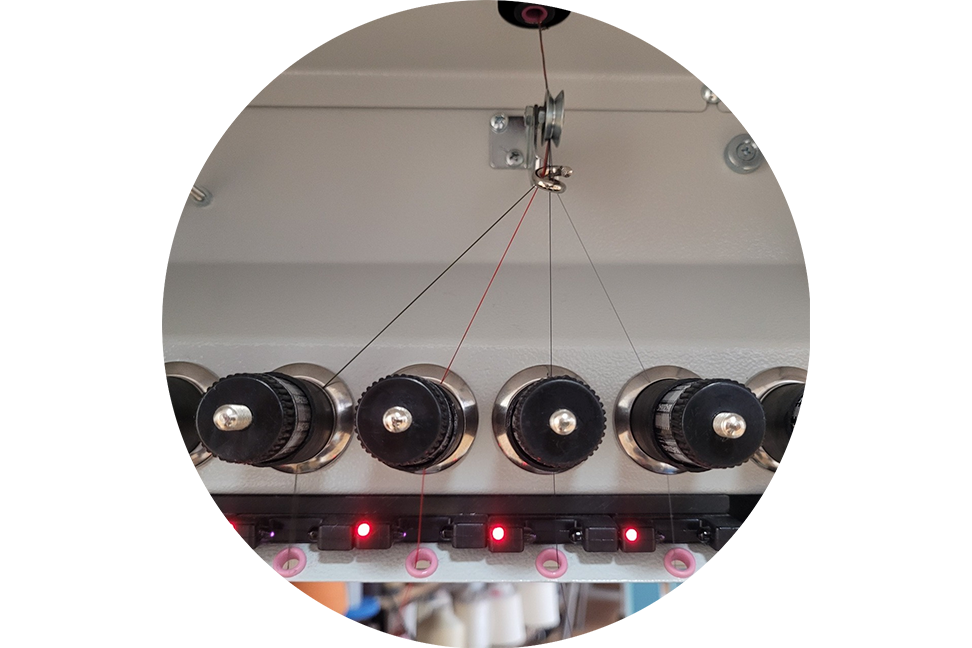

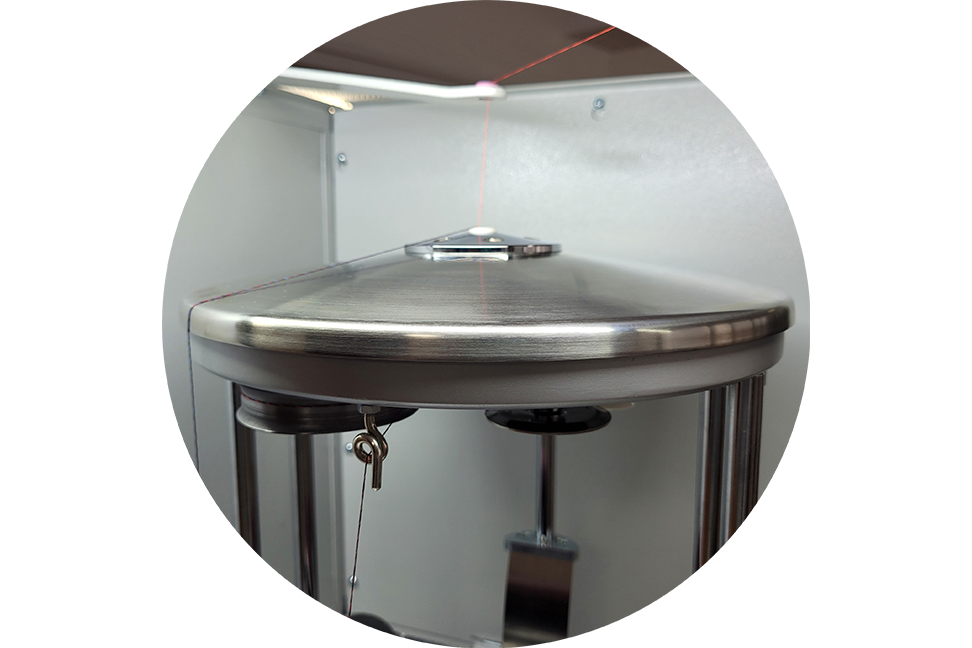

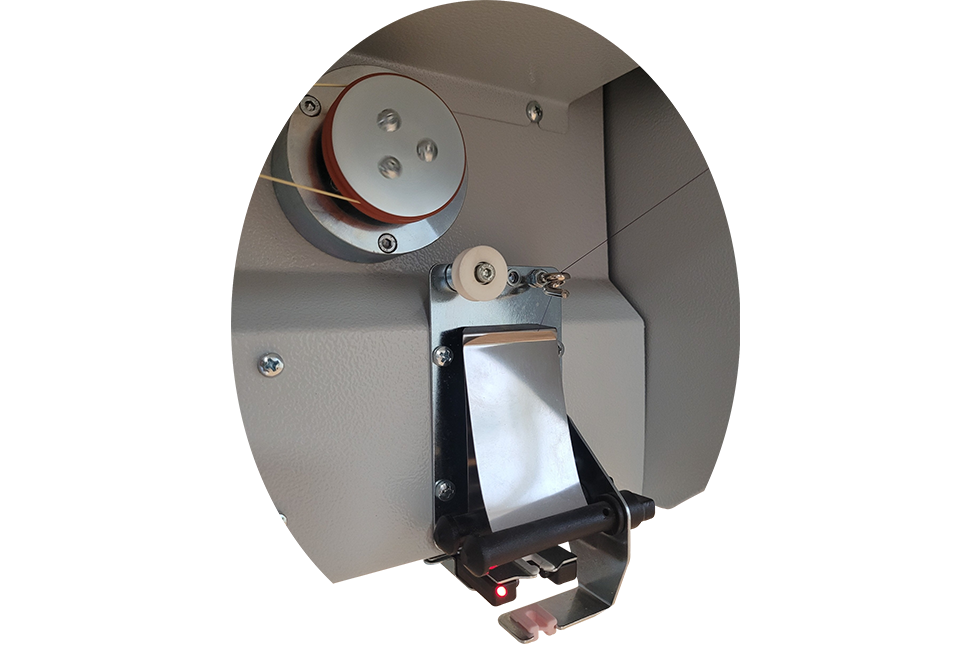

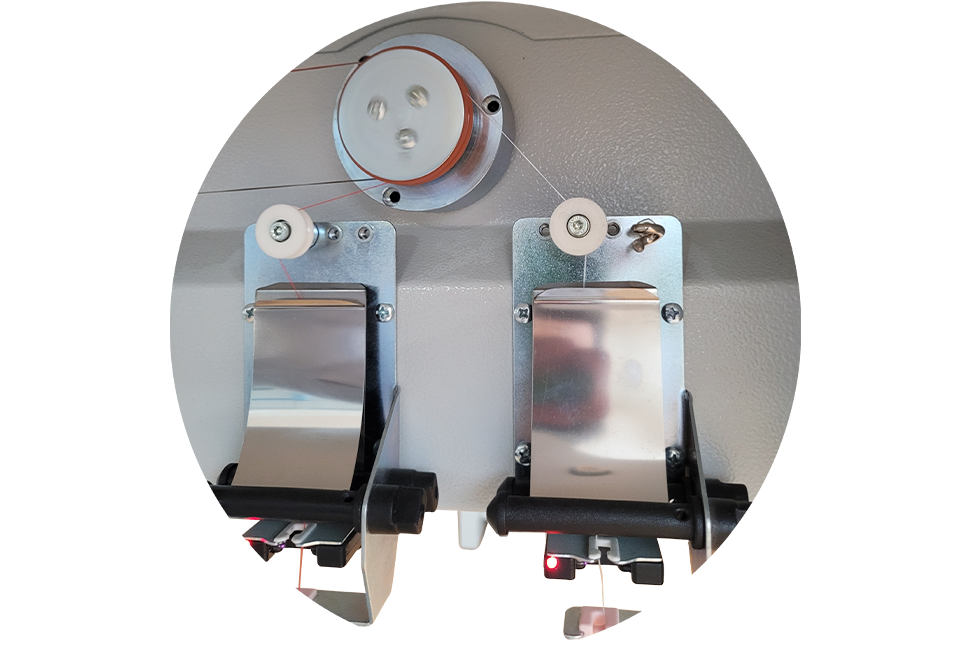

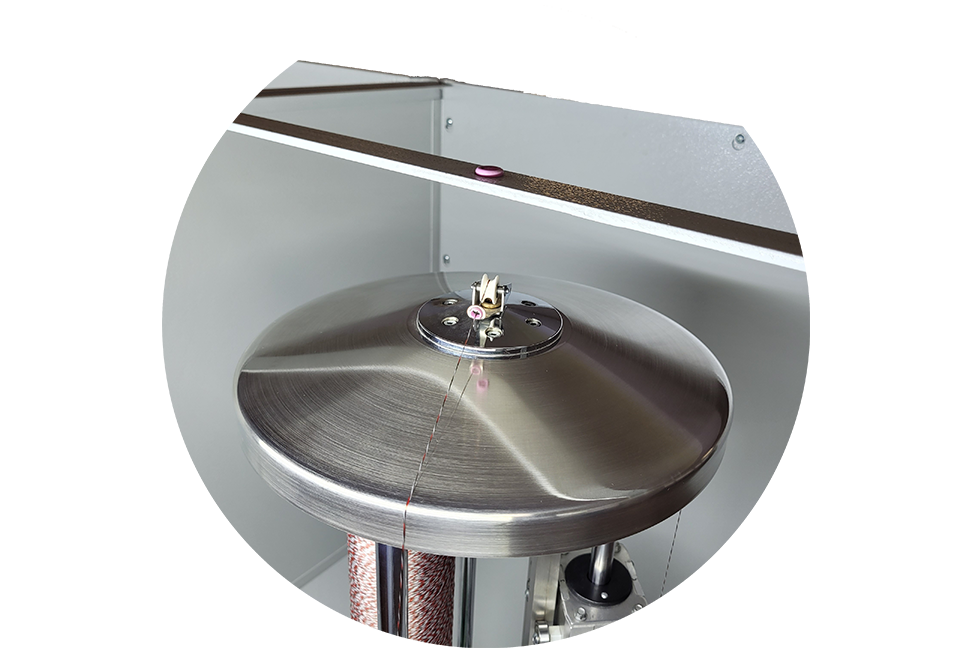

Ultra-Sensitive optical yarn sensors

It automatically stops the machine when the yarn breaks. In this way, it protects both your yarn quality and your machine.

for Filament + Stable Yarn

DirecTwist ®2C6″

It’s time to meet the most inclusive and best-selling machine in the DirectTwist series. You can easily twist and cover your staple fiber and continuous filaments with the highest level of efficiency.

As a result of its compact design, it is possible to create the combinations of your dreams for production, sample and R&D purposes.

| Maximum twisting speed | Up to 14.000 twist/minute |

| Maximum twist value | Up to 2.000 twist/meters |

| Maximum production speed | Up to 200 meters/minute |

| Total twisted yarn thickness | 100 Nm to 1.8 Nm (~90 Denier to ~5.000 Denier) |

| Take-up cone size | 170 mm length conical cone or cylindrical cone |

| Max. take-up cone diameter | 220 mm |

| Max. yarn plies to be twisted | Unlimited |

| Yarn break sensors | 8 sets optical sensors and the optional capacitive sensor for elastane |

Optional Programmable Elastane Feeder

It feeds your Lycra/Elastane yarns at a rate of 10%-90% and allows them to be twisted together with any type of yarn.

Waxing Device

Thanks to the convenience of the powered waxing device, the knitting process is facilitated.

Inner Yarn Break

In case of yarn breakage inside the twisting unit, it stops the machine quicker.

Twisting and Covering is easier than ever!

You can realize combinations of your dreams with different twisting and covering methods on the same machine.

Precise yarn feeding systems

You can maximize the efficiency of the winding and twisting process with the yarn feeding system.

Optional Programmable Elastane Feeder

It feeds your Lycra/Elastane yarns at a rate of 10%-90% and allows them to be twisted together with any type of yarn

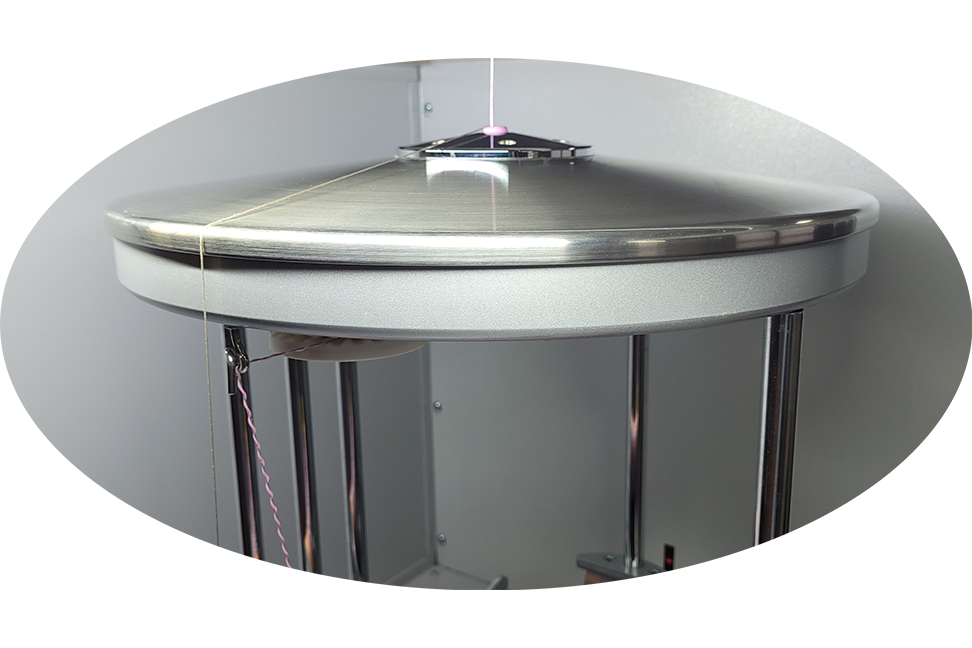

Ultra-Sensitive optical yarn sensors

It automatically stops the machine when the yarn breaks. In this way, it protects both your yarn quality and your machine.

for Filament + Stable Yarn

DirecTwist ®2C10″

You can twist and cover your thick yarns in one operation. Possible to use many thick yarns together with its design inspired by the C6” machine.

You can set all your parameters on the touch screen and monitor many parameters such as the remaining production time.

| Maximum twisting speed | Up to 10.000 twist/minute |

| Maximum twist value | Up to 1.000 twist/meters |

| Maximum production speed | Up to 200 meters/minute |

| Total twisted yarn thickness | 100 Nm to 0.5 Nm (~90 Denier to ~20.000 Denier) |

| Take-up cone size | 290 mm length conical cone or cylindrical cone |

| Max. take-up cone diameter | 260 mm |

| Max. yarn plies to be twisted | Unlimited |

| Yarn break sensors | On optional external creel. Wiring is provided for custom creels |

Inner Yarn Break

In case of yarn breakage inside the twisting unit, it stops the machine quicker.

PreTwist-C

It allows the S and Z twisting of your yarns to be done in a single operation. PreTwist-C can be produced up to 7 heads. It helps you to perform the S+Z operation you request as quickly as possible.

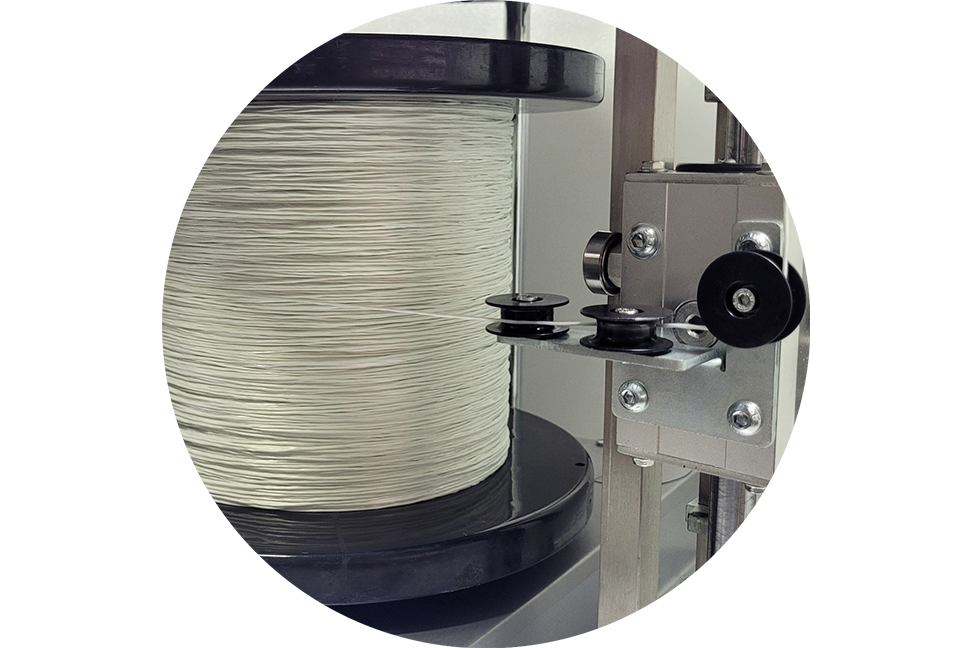

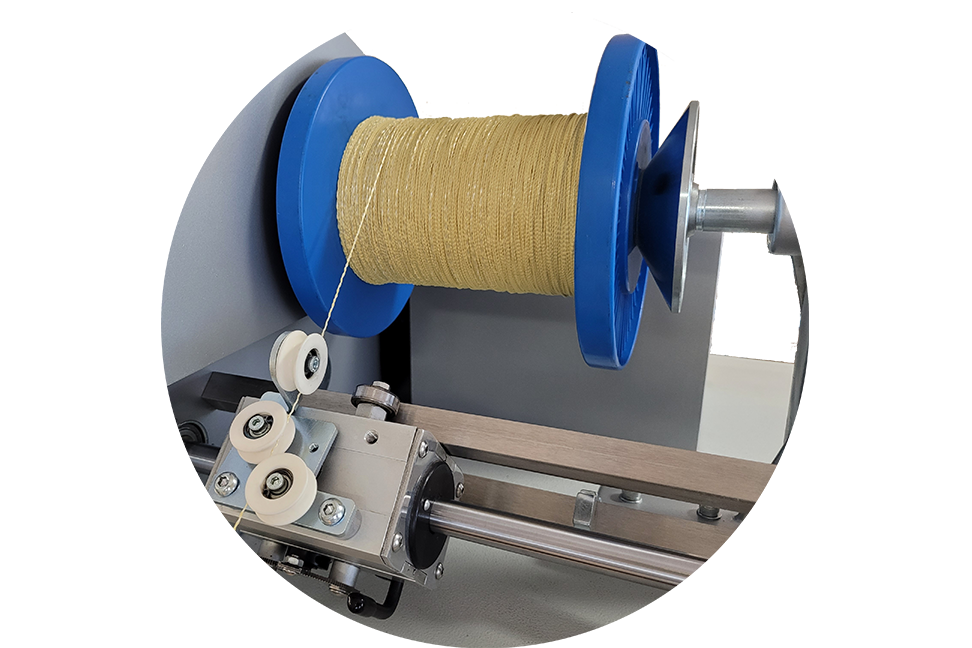

External Creel

External Creel allows working with multiple DirecTwist machines. It automatically stops the machine when the yarn breaks. The yarn tension is adjustable with tension discs. They are conventional creel systems designed to achieve optimum efficiency.

Twisting and Covering is easier than ever!

You can realize combinations of your dreams with different twisting and covering methods on the same machine.

Precise yarn feeding systems

You can maximize the efficiency of the winding and twisting process with the yarn feeding system.

Optional Programmable Elastane Feeder

It feeds your Lycra/Elastane yarns at a rate of 10%-90% and allows them to be twisted together with any type of yarn

for Technical Yarn

DirecTwist ® 2D6″

You can perform twisting and covering processes with your technical yarns such as carbon, glass, metal, aramid etc. It is also possible to use any type of yarn. Thanks to its high-tech design, you can produce your yarn from the first meter to the last meter. You can become the new star of the technical textile industry by meeting the world’s best twisting machine.

| Maximum twisting speed | Up to 8.000 twist/minute |

| Maximum twist value | Up to 1.700 twist/meters |

| Maximum production speed | Up to 82 meters/minute |

| Total twisted yarn thickness | 100 Nm to 0.9 Nm (~90 Denier to ~10.000 Denier) |

| Take-up cone size | 160 mm length double-flanged bobbin |

| Max. take-up cone diameter | 160 mm |

| Max. yarn plies to be twisted | Unlimited |

| Yarn break sensors | On optional external creel. Wiring is provided for custom creels. |

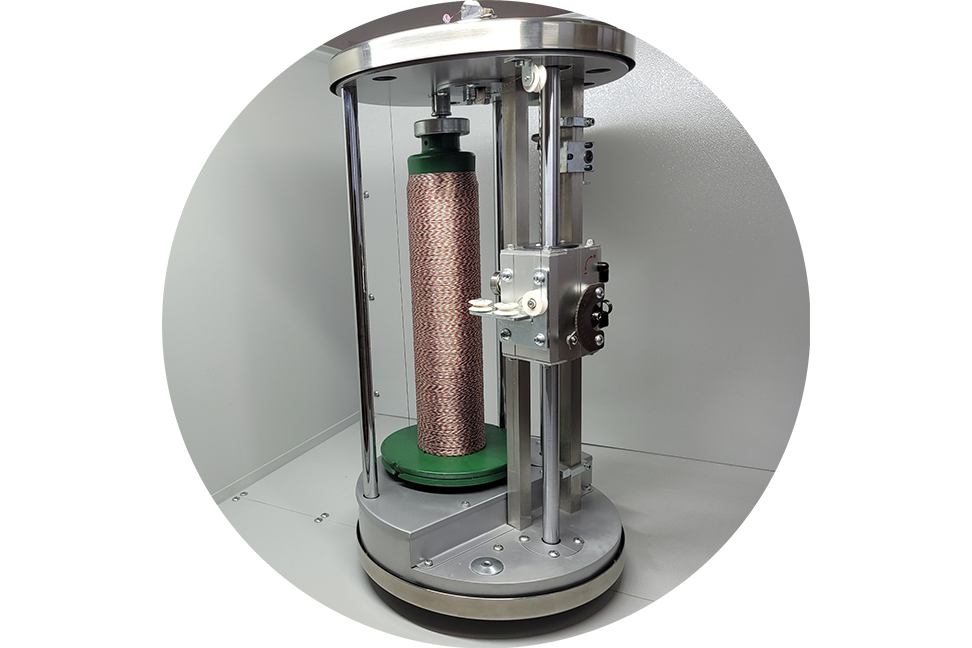

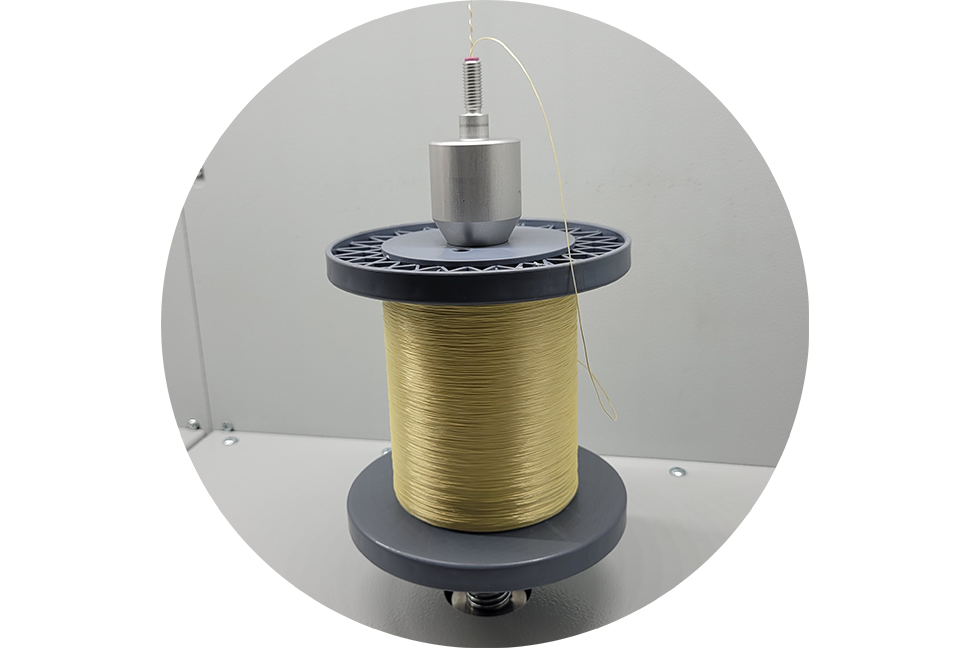

Servo Bobbin Feeder

Thanks to the smart systems on it, it provides feeding to the twisting machine with the most accurate tension setting even for the most sensitive yarns.

Magnetic Creel

It is the creel system that makes the tension adjustment over the bobbin instead of yarn. It is designed for the tension of thin metal yarns.

Twisting and Covering is easier than ever!

You can realize combinations of your dreams with different twisting and covering methods on the same machine.

for Technical Yarn

DirecTwist ® 2D10″

You can perform twisting and covering processes in the best way by wrapping your fragile yarns on a milk bottle type bobbin. You can use this machine with your technical yarns which has been developed with high-level engineering studies.

| Maximum twisting speed | Up to 10.000 twist/minute |

| Maximum twist value | Up to 1.000 twist/meters |

| Maximum production speed | Up to 82 meters/minute |

| Total twisted yarn thickness | 100 Nm to 0.9 Nm (~90 Denier to ~10.000 Denier) |

| Take-up cone size | 345 mm length single flanged bobbin |

| Max. take-up cone diameter | 160 mm |

| Max. yarn plies to be twisted | Unlimited |

| Yarn break sensors | On optional external creel. Wiring is provided for custom creels. |

Servo Bobbin Feeder

Thanks to the smart systems on it, it provides feeding to the twisting machine with the most accurate tension setting even for the most sensitive yarns.

External Creel

External Creel allows working with multiple DirecTwist machines. It automatically stops the machine when the yarn breaks. The yarn tension is adjustable with tension discs. They are conventional creel systems designed to achieve optimum efficiency.

Twisting and Covering is easier than ever!

You can realize combinations of your dreams with different twisting and covering methods on the same machine.

for Technical Yarn

DirecTwist ® 2D10″ L

You can twist and cover your thick technical yarns in one operation. It is possible to use many technical yarns with its design inspired by the D6 machine.

| Maximum twisting speed | Up to 6.000 twist/minute |

| Maximum twist value | Up to 1.200 twist/meters |

| Maximum production speed | Up to 82 meters/minute |

| Total twisted yarn thickness | 100 Nm to 0.5 Nm (~90 Denier to ~20.000 Denier) |

| Take-up cone size | 250 mm length double-flanged bobbin |

| Max. take-up cone diameter | 250 mm |

| Max. yarn plies to be twisted | Unlimited |

| Yarn break sensors | On optional external creel. Wiring is provided for custom creels. |

Servo Bobbin Feeder

Thanks to the smart systems on it, it provides feeding to the twisting machine with the most accurate tension setting even for the most sensitive yarns.

External Creel

External Creel allows working with multiple DirecTwist machines. It automatically stops the machine when the yarn breaks. The yarn tension is adjustable with tension discs. They are conventional creel systems designed to achieve optimum efficiency.

Twisting and Covering is easier than ever!

You can realize combinations of your dreams with different twisting and covering methods on the same machine.

for Smart Textiles & Wearable Electronics

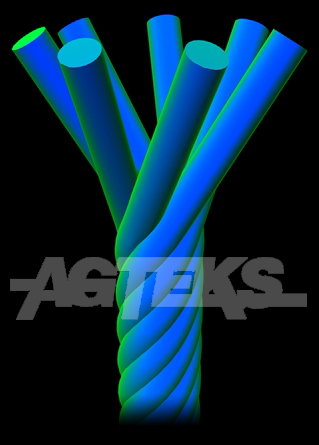

DirectCover 2S

It is the machine that can perform both S and Z covering processes in one operation at the same time. You can realize your dream covering operation with 100% covering for all kind of yarns.

| Maximum revolutions | Up to 6.000 revolutions/minute |

| Maximum twist value | Up to 6.500 twist/meters |

| Maximum production speed | Up to 20 meters/minute |

| Bobbin size | Up to 95 mm inner, 310 mm outer diameter, 290 mm length |

| Take-up cone size | 160 – 250 mm length double-flanged bobbin |

| Max. yarn plies for core yarn | Unlimited |

Servo Bobbin Feeder

Thanks to the smart systems on it, it provides feeding to the twisting machine with the most accurate tension setting even for the most sensitive yarns.

No limit to creativity!

Perform wonders in your R&D and special production processes by running the S+Z double covering operation at the same time.

Precise yarn feeding systems

Perform your covering processes in the most efficient way thanks to the superior design of yarn feeding.