With today’s increasing competition, facts such as cost reduction and quality improvement pave the way for serious quality processes in textile, but great efforts are made to ensure these. The main reason for the increased competition is that globalizing brands appeal to similar consumer groups, that is, the increase in accessibility has caused the markets to shrink. This situation brings with it a brutal price and quality comparison.

The principle of raising the quality has now become the basic and main rule of enterprises. We feel the effects of quality control from fiber production until the moment when the products meet the end consumer. We see heavy effects not only on the presentation of the products of the determined quality to the customer, but also on the process efficiencies that will be achieved by increasing the production efficiency. While providing the opportunity to progress up to a certain point in fabric quality control processes, the human factor, which is the most important factor, has always been the biggest factor. With today’s technologies, with the big breakthroughs in microprocessors and sensors, artificial intelligence technology has been stepped in. Thanks to these steps, the work to take the basic steps of eliminating the human factor has started, and the most important effects will be the progress to be made in the capture of color and physical errors. As AGTEKS company, which has been hosting innovative studies on this subject for many years, it believes in continuous improvement in color controls and catching physical defects in production. The quality control that manifests itself from the yarn, thanks to today’s Agteks technologies, make us user-friendly with its ideas and products in which time, production efficiency, cost reduction and human factor are minimized, and it has brought a new breath to classical quality controls.

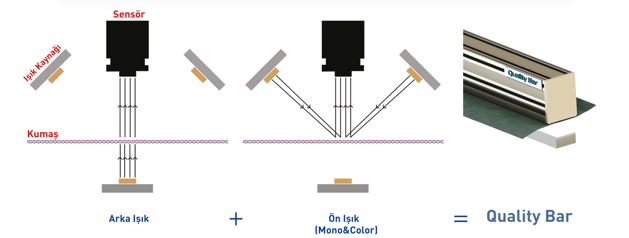

Traditional fabric quality control physical defects are made by trained operators following the flowing fabric over a vertical table. When all human factors are put aside, an operator can control 15 meters of fabric per minute, while these speeds can be up to 50 meters thanks to scanning systems and are provided with maximum accuracy.

Thanks to these systems, which recognize the fabric regardless of weaving or knitting and compare it with the other meters by comparison method, a system that learns the fabric by itself has been created.