The raw material of the fabric is yarn. The yarn is formed by bringing the fibers together. Therefore, the quality and strength of the yarn directly depend on the properties of the fibers. In order to eliminate the defects on the yarn, it is necessary to check variation.

Unevenness on the yarn; occurs in weaving, knitting, dyeing, finishing, and ready-made clothing. These defects cannot be corrected in later stages. For these reasons, it is absolutely necessary to check for unevenness while the yarn is in the production phase.

The quality of the yarn is determined by TSE, ASTM, ISO, and “unevenness values” according to the type and quality of the yarn produced. With relatively less human factor in yarn quality control systems, device manufacturers offer additional units that perform quality controls on the production they concentrate on.

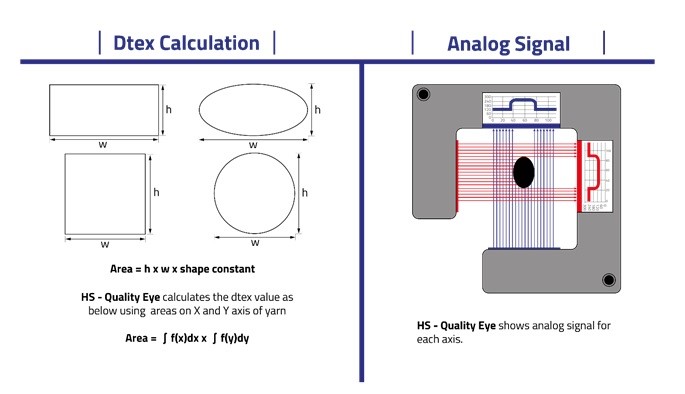

Thanks to the optical scanning systems we have developed as Agteks, we have focused on developing systems that will catch different yarn quality defects at the same time and present them together. In this way, it has adopted the way of providing comfort in the related productions by producing solutions for the expectations of the yarn manufacturers